Order now to enhance your production efficiency and product quality!

Key Features

-

Multi‑Zone Temperature Control

Independently controlled in 4–8 zones, each programmable to specific temperatures to achieve precise drying or curing. -

Forced Hot‑Air Circulation

Equipped with a powerful convection system and return‑air distribution design to ensure uniform temperature across the oven chamber, eliminating cold spots. -

Energy Saving & Environmentally Friendly

Standard high‑efficiency insulation materials and double‑seal doors minimize heat loss; optional heat recovery systems further reduce energy consumption. -

Flexible Conveyor System

Choice of chain‑plate, mesh belt, or roller conveyors with stepless speed adjustment to match varying production rates; modular design simplifies maintenance and line expansion. -

Intelligent Control

PLC with integrated touchscreen interface supports temperature profiling, remote monitoring, and automatic fault diagnostics to boost efficiency and automation. -

Safety & Reliability

Features ground‑fault protection, over‑temperature alarms, and emergency stop buttons for multiple layers of operational safety.

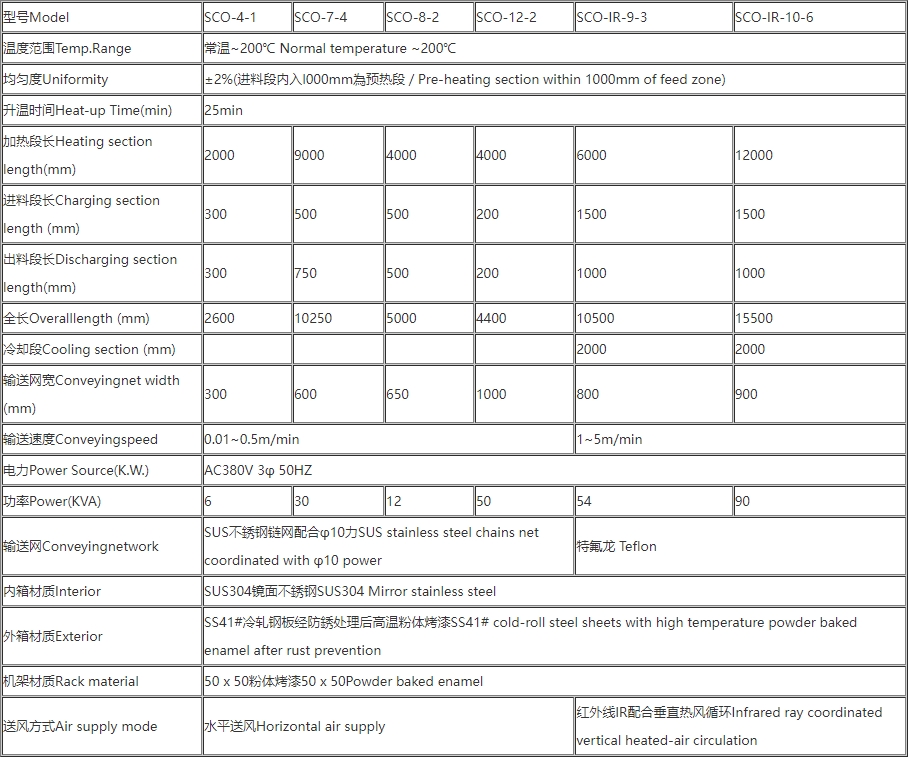

Technical Specifications

| Parameter | Range / Options |

|---|---|

| Number of Zones | 4 / 6 / 8 (customizable) |

| Temperature Range | Ambient to 300 °C (up to 400 °C optional) |

| Conveyor Speed | 0.5–10 m/min (stepless adjustment) |

| Conveyor Width | 300–2000 mm (customizable) |

| Heating Method | Electric / Steam / Hot‑Air |

| Total Power | 20 kW–200 kW (depending on length & zones) |

| Oven Length | 3 m–30 m (modular assembly) |

| Insulation | High‑temperature rock wool + steel outer panels |

| Control System | PLC with 7″ TFT touchscreen |

| Safety Protections | Over‑temperature shutdown, ground‑fault protection, emergency stop |

Typical Applications

-

Coated parts (automotive components, appliance panels, furniture trims)

-

Ink drying for printing (labels, packaging materials, veneers)

-

Food dehydration (fruits, seafood, baked goods)

-

Electronics baking (PCBs, surface‑mount components)

-

Textile finishing (non‑woven fabrics, functional fibers)

Installation & Maintenance

-

Installation

-

Assemble modular oven sections per site layout and secure mounting bolts;

-

Connect power or steam lines and configure the conveyor drive;

-

Before first use, inspect all fans, heaters, and temperature sensors.

-

-

Commissioning

-

Use the touchscreen to program temperature profiles and conveyor speed;

-

Run empty to verify even temperature distribution and airflow before introducing products.

-

-

Maintenance

-

Regularly clean air ducts and filters; check chain/mesh belt tension;

-

Inspect insulation panels and door seals, replacing any worn components;

-

Calibrate and service heating elements and control instruments according to the maintenance manual.

-