Order now to boost your heating efficiency and equipment performance!

Key Features

-

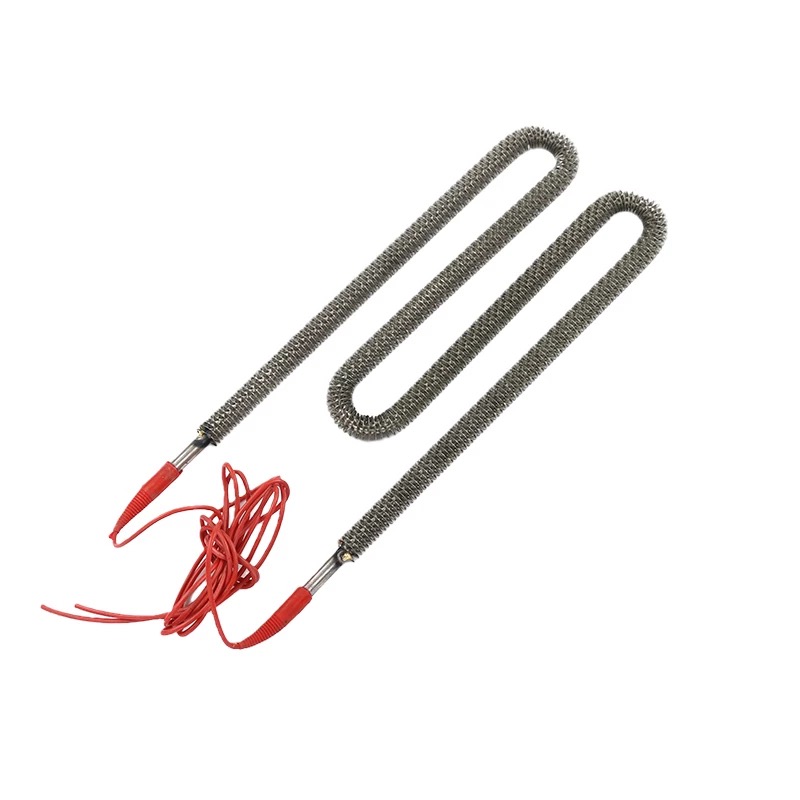

Rapid Temperature Rise

Made with premium resistance alloys (NiCr, FeCrAl) or ceramic heating cores for quick thermal response and fast reach of set temperatures. -

Uniform Heating

Heating plates use composite lamination technology, and tubular elements are densely arranged to ensure even heat distribution with no hot spots. -

Energy Saving & Eco‑Friendly

Surface treatments such as nitriding or nickel plating boost thermal conductivity and extend service life; efficient insulation design minimizes heat loss. -

High‑Temperature & Corrosion Resistance

Tubes can be made of stainless steel or aluminum alloy; heating plates on ceramic substrates, suitable for –50 °C to +800 °C conditions and various chemical environments. -

Flexible Installation

Tubular elements support direct‑insertion, flange, threaded, or clamp connections; heating plates can be fixed by adhesive, screws, or embedded into grooves to meet diverse installation needs. -

Customizable Specifications

Power, voltage, length, and thickness are all customizable, and options include single‑phase, three‑phase, and DC power supplies.

Technical Specifications

| Parameter | Typical Range / Options |

|---|---|

| Power Density | 5 W/cm² – 30 W/cm² (heating plates) |

| Power | 50 W – 10 000 W (tubular elements) |

| Voltage | 12 V / 24 V / 110 V / 220 V / 380 V |

| Operating Temp. | –50 °C to +800 °C |

| Element Size | Tube Ø 6 mm–Ø 25 mm; Plate thickness 0.5–2 mm |

| Connection Types | Flange, threaded, clamp, direct insertion |

| Materials | Stainless Steel 304/316L, Aluminum Alloy, Ceramic Substrate |

| Protection Rating | IP00 – IP67 (depending on housing & cables) |

Typical Applications

-

Air heating (ducts, ovens, dryers)

-

Liquid heating (oil tanks, immersion heaters)

-

Mold heating (injection molds, extrusion molds)

-

Laboratory equipment (incubators, thermostatic chambers)

-

Household appliances (electric kettles, heated blankets)

-

Any application requiring localized or surface heating

Installation & Maintenance

-

Installation

-

Confirm matching of power supply voltage and rating;

-

Ensure tight contact between heating element and workpiece to avoid air gaps;

-

Provide reliable grounding to prevent leakage.

-

-

Commissioning

-

Power up gradually and monitor sensors and controllers for proper response;

-

Adjust power or temperature settings step by step to prevent overshoot.

-

-

Maintenance

-

Regularly inspect terminals, insulation layers, and sealing rings;

-

Clean surface dust and debris to maintain adequate heat dissipation;

-

On fault detection, immediately power down, stop operation, and replace or repair the heating element.

-