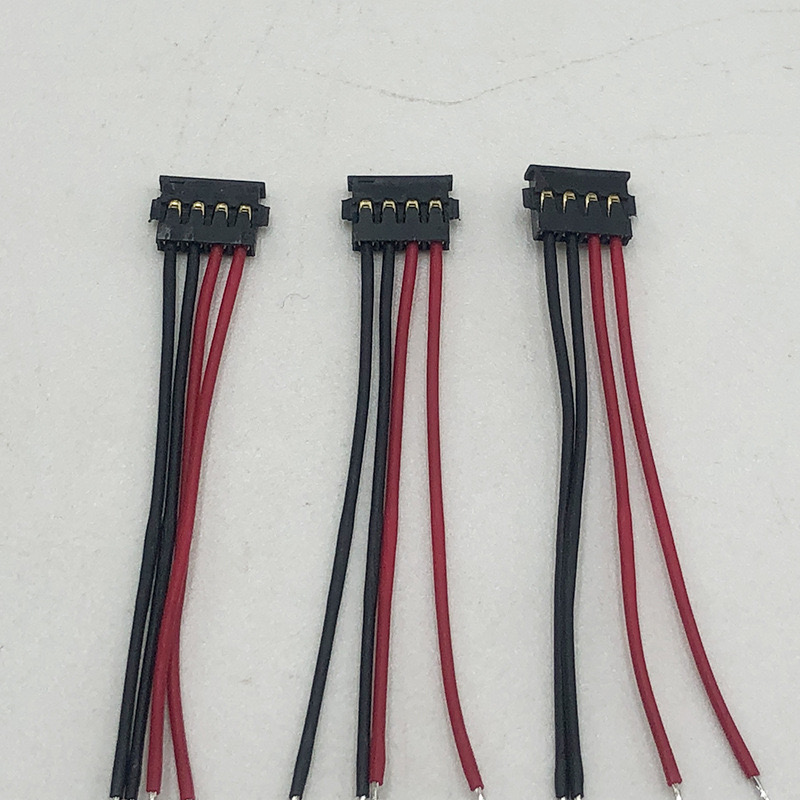

High-quality terminal connector assemblies, safeguarding your vehicle’s electrical system!

Key Features

-

Integrated Design

Terminals and connectors are precisely matched with mature crimping and assembly processes, reducing assembly time and improving production efficiency. -

High-Quality Terminal Materials

Made from high-conductivity copper alloys with tin or gold plating, minimizing contact resistance and enhancing signal stability. -

Secure and Reliable Connection Structure

Connectors feature tight locking mechanisms and vibration-resistant designs to ensure long-lasting stable mating. -

Wide Range of Specifications and Compatibility

Supports multiple pin counts and various connection types (pin housings, blade terminals, ring terminals, etc.), compatible with mainstream brands such as AMP, Molex, Yazaki, and Sumitomo. -

Excellent Environmental Resistance

Suitable for harsh conditions including high temperature, humidity, and exposure to oil; operating temperature range from –40°C to +150°C with good corrosion resistance. -

Customizable Production

Terminals, connector types, wire gauge ranges, and lengths can be customized to meet different vehicle models and manufacturing requirements.

Technical Specifications

| Item | Details / Description |

|---|---|

| Terminal Material | Copper alloy (tin-plated/gold-plated) |

| Connector Material | Engineering plastics such as PA66, PBT |

| Wire Gauge Range | 0.2mm² – 16mm² (customizable) |

| Pin Count | 1 – 40 pins |

| Operating Temp. | –40°C to +150°C |

| Contact Resistance | ≤10mΩ |

| Mating Durability | ≥100 mating cycles |

| Protection Rating | IP67 / IP68 (model dependent) |

| Standards | ISO 9001 / IATF 16949 / RoHS / REACH |

Applications

-

Primary and branch wiring harness systems

-

Engine control units (ECUs)

-

Automotive lighting and signaling systems

-

Sensor and actuator connections

-

High and low voltage cable interfaces in new energy vehicles