Order now to optimize your heating process with our high‑performance flanged heating tubes!

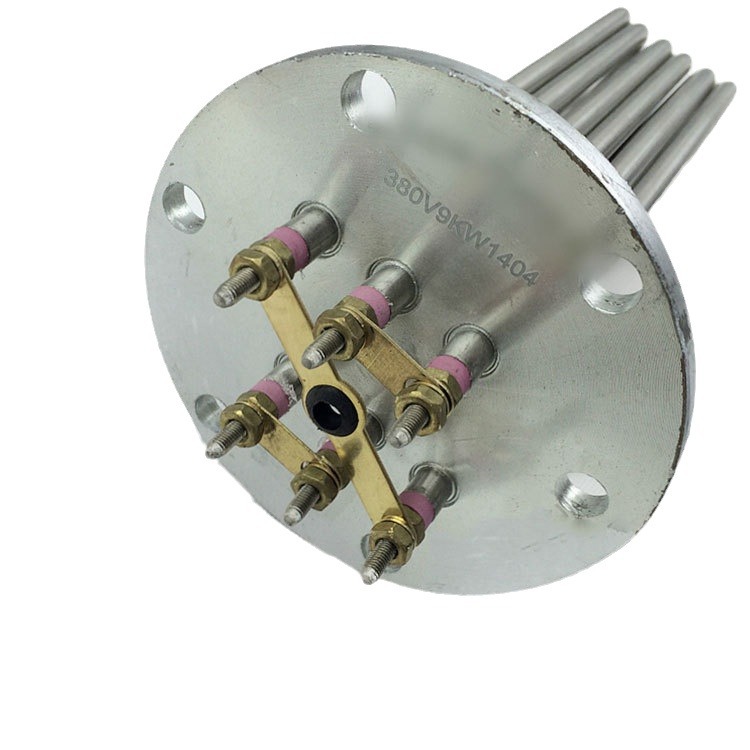

Key Features

-

High Heating Efficiency

Made from premium alloy heating elements with nickel-plated surfaces to resist oxidation. Each tube is thoroughly aged and tested, offering fast heat‑up times and quick thermal response. -

Reliable Sealing

The flange mates tightly against the equipment’s flange face, using high‑temperature, pressure‑resistant gaskets to prevent any media leakage under demanding conditions. -

Excellent Corrosion Resistance

Special anti‑corrosion treatment on the tube surface makes it suitable for acidic, alkaline, oily, and high‑humidity environments. -

Easy Installation & Maintenance

Flange‑mounted design requires no additional support; the heating tube can be quickly removed and replaced for maintenance. -

Multiple Material Options

Flange materials include carbon steel, 304 or 316L stainless steel, etc., to suit different media and temperature requirements.

Technical Specifications

| Parameter | Range / Options |

|---|---|

| Power | 1 kW – 50 kW (customizable) |

| Voltage | 220 V / 380 V / 440 V / 600 V |

| Tube Diameter | Ø 8 mm / Ø 10 mm / Ø 12 mm / Ø 16 mm |

| Tube Length | 100 mm – 2000 mm (customizable) |

| Flange Size | DN25 – DN300 (standard or custom) |

| Operating Temp. | –50 °C to +650 °C |

| Operating Pressure | ≤ 2.5 MPa |

| Protection Class | IP65 |

Typical Applications

-

Chemical processing equipment (storage tanks, reactors, heat exchangers)

-

Food & beverage industry (sterilization tanks, insulation tanks)

-

Plastics & rubber machinery (injection molding, extruders)

-

Oil processing (oil tanks, lubrication oil heating)

-

Water treatment (hot water tanks, evaporators)

-

Any vessel or piping requiring controlled heating

Installation & Maintenance

-

Installation

Align the heating tube flange with the equipment flange face, insert the high‑temperature gasket, and tighten bolts evenly. Connect the correct power supply and ensure proper grounding. -

Commissioning

Energize the tube and monitor current and temperature to confirm operation within rated limits. -

Maintenance

Periodically check flange bolts for tightness and inspect gaskets for wear. Tubes can be quickly removed for replacement during scheduled shutdowns.

Reviews

There are no reviews yet.